Trenchless Pipe Bursting

Replace your sewer with minimal excavation

We fix these problems

Our common solutions

A full replacement of via excavation where you replace all sewer pipes is expensive since you have to excavate, cutting the road, the sidewalk and the flooring or trees that you love so much.

There is always the risk of hitting waterlines, gas lines, electric and fiber optic cables not to mention that old foundations can be compromised. And who is looking forward to the dump trucks, heavy equipment and restricted access to street and home for multiple days except for four year old sons?

Having deep holes where people are accidents and lawsuits waiting to happen.

When a traditional sewer fails it is often at the joints. Here you find the root intrusion, earth - mud and gravel infiltration and sometimes full collapse.

Due to minimal excavation with two pits versus full length excavation the cost savings on landscape restoration, flooring replacement, concrete patching etc. is limited to only two areas in most installations thus saving as much hardscape and greenspace as possible. Where excavation might take out that new driveway or retaining wall many times this is the solution to avoid those costly repairs.

With two pit locations and extensive utility marking our risk to utilities and surrounding infrastructure is reduced by 80 percent.

Connections are fused together and verified before being pulled into place. HDPE pipe has been tested to the highest of standards and is a superior alternative to PVC.

Our Solution

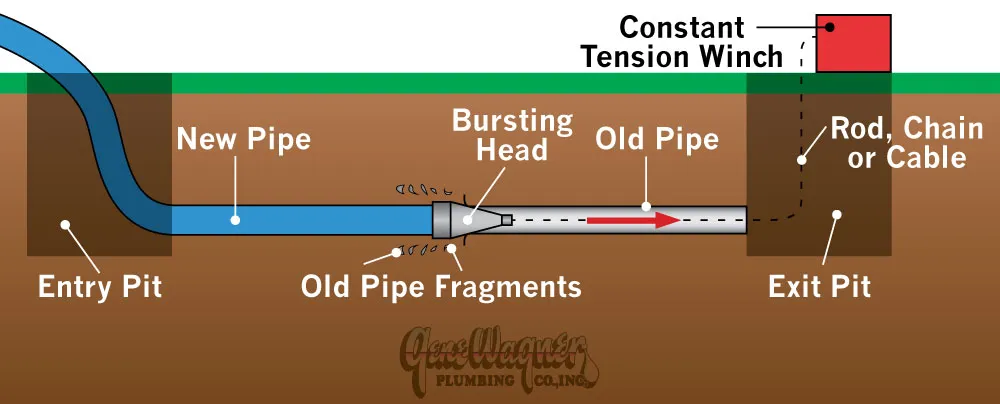

Pipe Bursting is very similar to modern directional drilling techniques. It has the ability to replace long runs of pipe without disturbing major areas of hardscape and greenspace. Ever wonder what that crew with the big roll of fiber optic cable is doing next to the roadway. They are running new fiber optic internet lines in a very similar manner. Only difference is we will use our existing pipe as a guide for our new pipe where they are using the drill to guide the pathway.

Here is how Pipe Bursting a sewer works:

1. We locate the best access points

- We prefer outside access points (and so do you). Access points are 'clean-outs' which is a vertical riser pipe that provides access to the sewer at ground level.

- If there are no clean outs we can perform an inspection by pulling a toilet and can locate a spot that is ideal to install a clean out.

- Manhole access points are the also an option if present and can even bring down the cost of your project.

2. We map the existing sewer pipes using a camera

- We identify connecting pipes and measure the diameter transitions and lengths of the sewer-line.

- We confirm the diameter of the affected existing pipes

- Additional access to connecting pipes is identified so that we can reinstate the connecting pipe when and where needed.

- A initial CCTV video will be made for documentation purposes.

3. We dig the access points

- When and where possible we use minimally invasive air digging technology to dig the pits when and where possibe.

- Once the holes are set we the run our cable and begin setting up the pipe bursting head.

- Some pipe will be fused in advance of the pull.

- Pipe bursting machine will be placed in the appropriate position within the holes.

4. We Burst a new pipe into place

- Once all preparation is complete we begin the process of bursting the new sewer line into place

- Once the pipe has been pulled through all necessary connections will be made and connections re connected when needed

- The holes will be backfilled, and the cleanup begins.

3B. We perform a final quality control inspection

- We complete the project with a final video inspection.

- This video recording is delivered to our clients.

Testimonial

Enter your text here...