Lining of Sewer pipes, Storm drains, Roof drains and Electrical conduit

Renew your Sewer without Costly Excavation

We fix these problems

Our common solutions

A full replacement of via excavation where you replace all sewer pipes is expensive since you have to excavate, cutting the road, the sidewalk, the floors.

There is always the risk of hitting waterlines, gas lines, electric and fiber optic cables not to mention that old foundations can be compromised. And who is looking forward to the dump trucks, heavy equipment and restricted access to street and home for multiple days except for four year old sons?

Having deep holes where people are accidents and lawsuits waiting to happen.

When a traditional sewer fails it is often at the joints. Here you find the root intrusion, earth - mud and gravel infiltration and sometimes full collapse.

Due to avoiding the cost of digging the cost savings on landscape restoration, flooring replacement, concrete patching and the digging itself are avoided. Where it might take two days of digging up an underground sewer the process of relining existing pipes via a so called 'clean out' (small existing access point) would take just one day.

We don't disturb the ground, there is no risk of utility strikes. We use the existing sewer as a mold for our 'cured-in-place' pipe.

We use LMK performance liner which has a 10 year manufacturing warranty and is field tested to last 50 years. The material is comparable to PVC but lacks the joints that can fail.

The liner is 4 millimeter thick (0.157 inch) and thus the diameter reduction of your pipes is minimal while flow is increased due to the absence of pipe joints.

Our Solution

Pipe lining is like modern day heart surgery. When you have a blockage in your artery the surgeon will look inside your artery with a camera and then place a stint to remove the blockage.

Just like that we will also use a camera to investigate your sewer pipe and then put our liner inside the existing pipes.

Placing a stint is much less risky than replacing your entire heart and the same is true for relining sewer pipes instead of full on replacing them!

Here is how relining a sewer works:

1. We locate the best access points

- We prefer outside access points (and so do you). Access points are 'clean-outs' which is a vertical riser pipe that provides access to the sewer at ground level.

- If there are no clean outs we can perform an inspection by pulling a toilet and can locate a spot that is ideal to install a clean out.

- Manhole access points are the also an option if present and can even bring down the cost of your project.

2. We map the existing sewer pipes using a camera

- We identify connecting pipes and measure the diameter transitions and lengths of the sewer-line.

- We confirm the diameter of the affected existing pipes

- Additional access to connecting pipes is identified so that we can reinstate the connecting pipe when and where needed.

- A pre-cleaning video will be made

3. We clean the sewer pipe

- Using cutting edge high speed millers with precision carbide cutting chains specifically sized to pipe-make up any blockage and buildup is removed.

- Because of these precision cutting tools are specifically sized to your pipe-make, they will not damage your existing sewer lines any further, unlike the commonly used tools used to remove roots and blockages from a sewer.

- The pipe will thus be cut to 'lining-standard'. Note that that this is much more precise than what your average drain cleaning company will perform.

- After this, we record the post-cleaning video to show that the original radius and flow line of the pipe is restored.

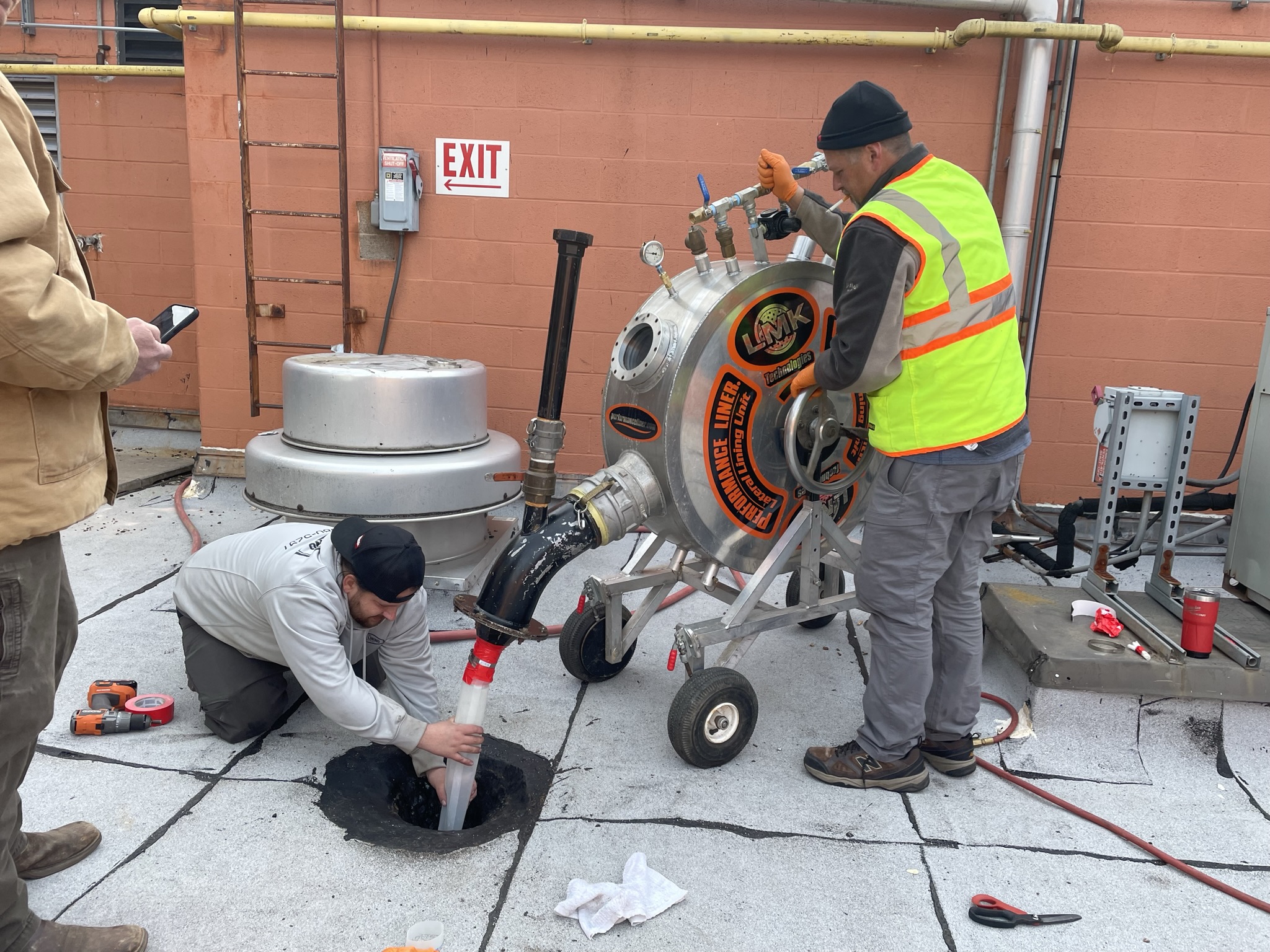

4. We insert the new liner

- Meanwhile we have prepared the new liner with a plastic resin

- The new liner is inserted into the sewer and inverted using air pressure

- The new liner will cure (harden) in place

- What is unique about our process is that we do the liner insertion via the clean out access point.

- This is a patented, licensed process with superior results compared to the non government approved knock off products.

3B. We perform a final quality control inspection

- We complete the project with another video inspection.

- This video recording is delivered to our clients.

- We place a sticker on the clean-out cap that denotes that the sewer has a liner installed.

Testimonial

Enter your text here...